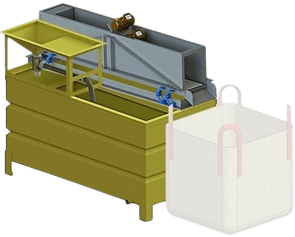

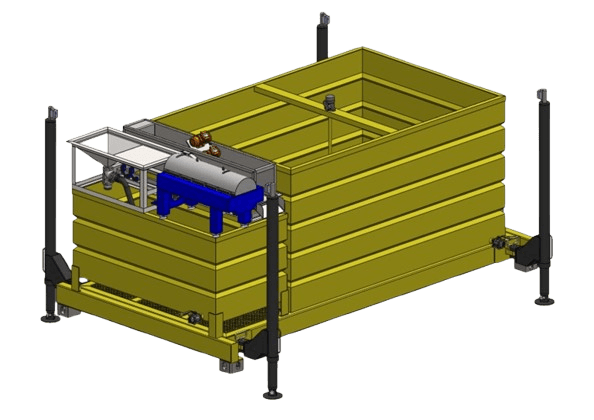

What do we do

OUR SOLUTIONS

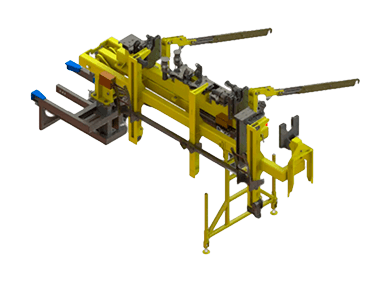

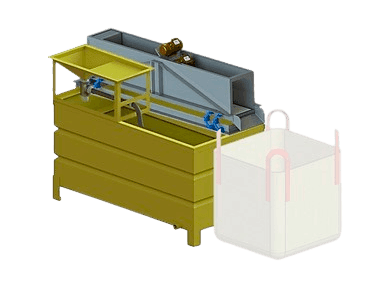

Incorporating automation into rod handling not only minimizes occupational hazards, but also optimizes uptime and improves accuracy in each borehole. This advancement is key to the success of drill hole operations, enabling our customers to maximize their throughput and minimize costs.

Nuestro diseño permite optimizar el espacio y hacer más con menos.

Gracias a su simplicidad, el tiempo requerido para poner en marcha y mover el equipo se ve reducido considerablemente.

Facilita la manipulación de barras y tubos interiores, permitiendo que una persona opere el equipo, lo cual disminuye la necesidad de un grupo de operadores.

Al simplificar y optimizar los procesos, se logra una disminución significativa en los costos, favoreciendo así la rentabilidad de nuestros clientes.

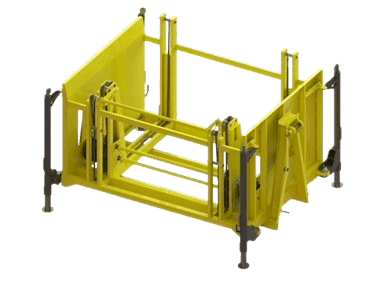

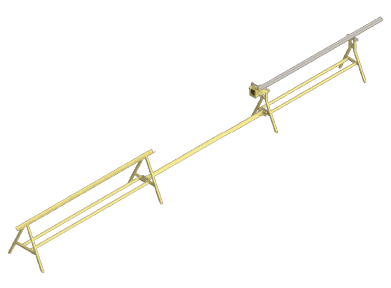

Our design allows you to optimize space and do more with less.

Thanks to its simplicity, the time required to start up and move the equipment is considerably reduced.

Security in automation

It facilitates the manipulation of bars and inner tubes, allowing one person to operate the equipment, which reduces the need for a group of operators.

By simplifying and optimizing processes, a significant reduction in costs is achieved, thus favoring the profitability of our clients.